Unified Fracture Design

Bridging the Gap Between Theory and Practice

About UFD

The word “unified” has been selected deliberately to denote both the integration of all the highly diverse technological aspects of the process, but also to dispel the popular notion that there is one type of treatment that applies to low-permeability and another to high-permeability reservoirs. It is natural, even for experienced practitioners to think so because traditional targets have been low-permeability reservoirs while the fracturing of high-permeability formations has sprung from the gravel pack and sand control practice.

Technical Description

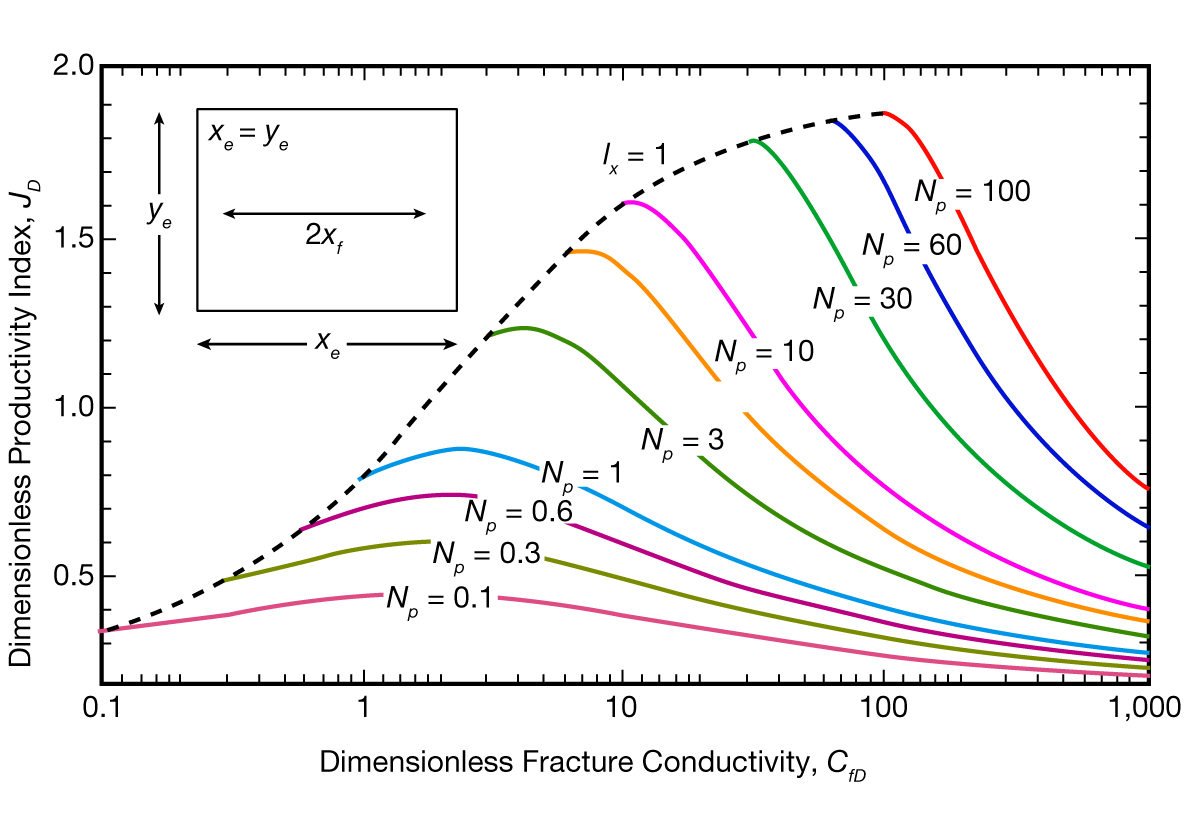

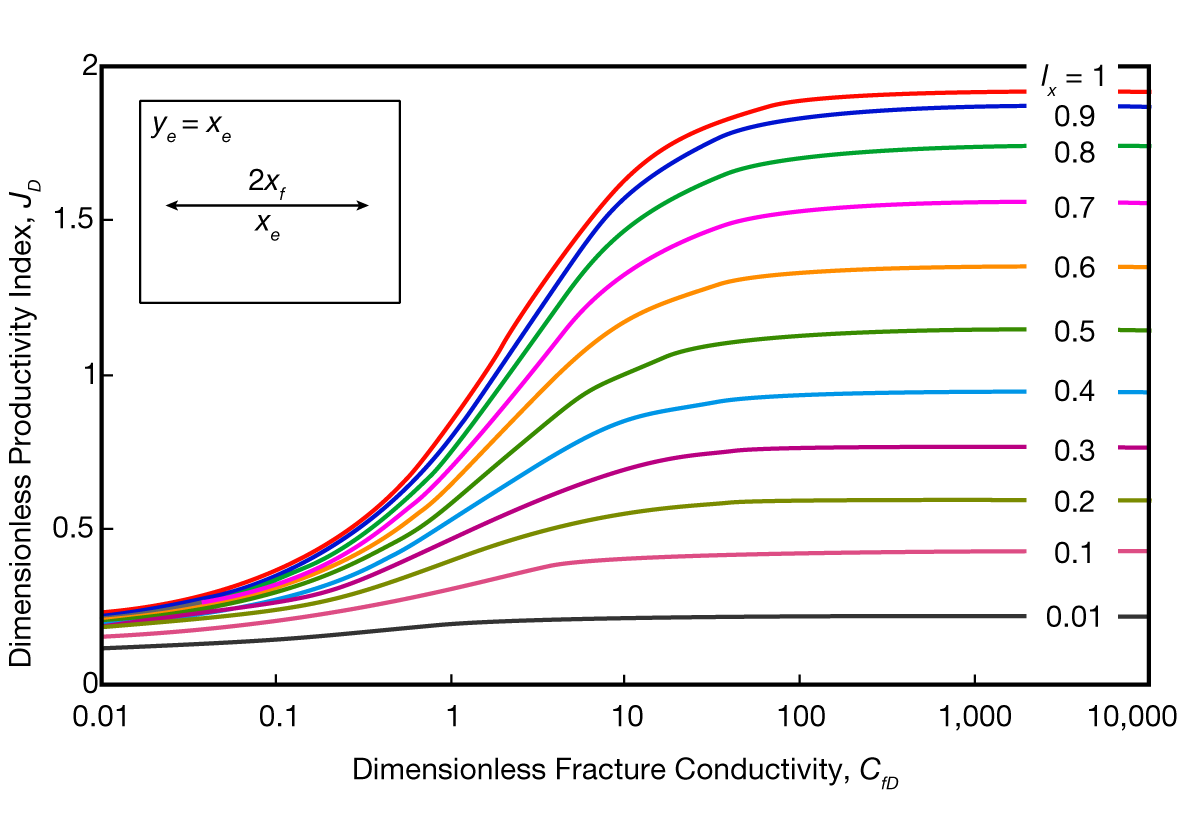

The key idea is that treatment sizes can be unified because they can be best characterized by the dimensionless Proppant Number. This dimensionless number determines the theoretically optimum fracture dimensions at which the maximum productivity or injectivity index can be obtained. Technical constraints should be satisfied in such a way that the design departs from the theoretical optimum only to the necessary extent. With this approach, difficult topics such as high- versus low-permeability fracturing, extensive height growth, non-Darcy flow, and prop pant embedment are treated in a transparent and unified way, providing the engineer with a logical and coherent design procedure.

While Unified Fracture Design techniques were designed for optimizing conventional reservoirs where typically only a single planar fracture is established around the perforations, many extrapolations of this theory can and have been made that apply to unconventional reservoirs where a complex fracture network is thought to be created during massive hydraulic fracture pumping.

In Unified Fracture Design, a very simple and straightforward performance indicator is considered: the pseudo-steady state productivity index. The improvement in this variable describes the actual effect of the propped fracture on well performance.

UFD Advantages

With the goal of UFD being to realize the maximum possible pseudo-steady state productivity index, fracture length and dimensionless fracture conductivity are the two primary variables that control the productivity index of a fractured well. Dimensionless fracture conductivity is a measure of the relative ease with which produced fluids flow inside the fracture compared to the ability of the formation to feed fluids into the fracture. In low permeability reservoirs, the fracture conductivity is de facto large, even if only a narrow propped fracture has been created and a long fracture length is needed. A post-treatment skin can be as negative as –7, leading to several folds-of-increase in well performance compared to the unstimulated well. For high permeability reservoirs, a large fracture width is essential for adequate fracture performance.

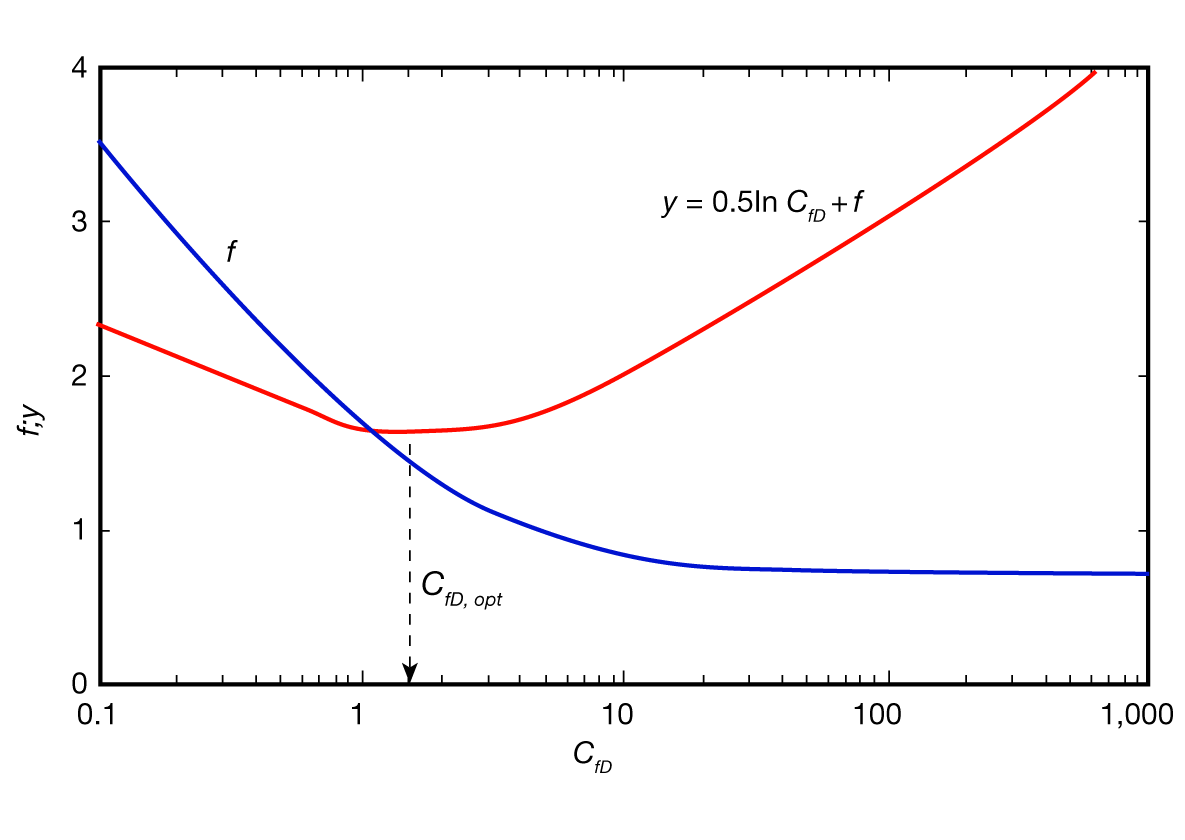

For a fixed volume of prop pant placed in the formation, a well will deliver the maximum production or injection rate when the dimensionless fracture conductivity is precisely, 1.6 as shown by Economides, Valko and Oligney in their seminal work “Unified Fracture Design: Bridging the gap between theory and practice”.

In Summary

In essence, larger values of the dimensionless fracture conductivity would mean relatively shorter than optimum fracture lengths and, thus, the flow from the reservoir into the fracture would be unnecessarily restricted. Dimensionless fracture conductivity values smaller than unity would mean less-than optimum fracture width, rendering the fracture as a bottleneck to optimum production.

The UFD approach provides a rapid analytical method for achieving the optimal fracture geometry. Designed for any combination of reservoir description and proppant volume and will result in physically optimized reservoir and well production. Coupled with design procedures to produce a pumping schedule capable of delivering the required geometry, this unified technique will equip a production engineer with a practical, optimal solution.

[event_rocket_calendar]

Comments are closed.